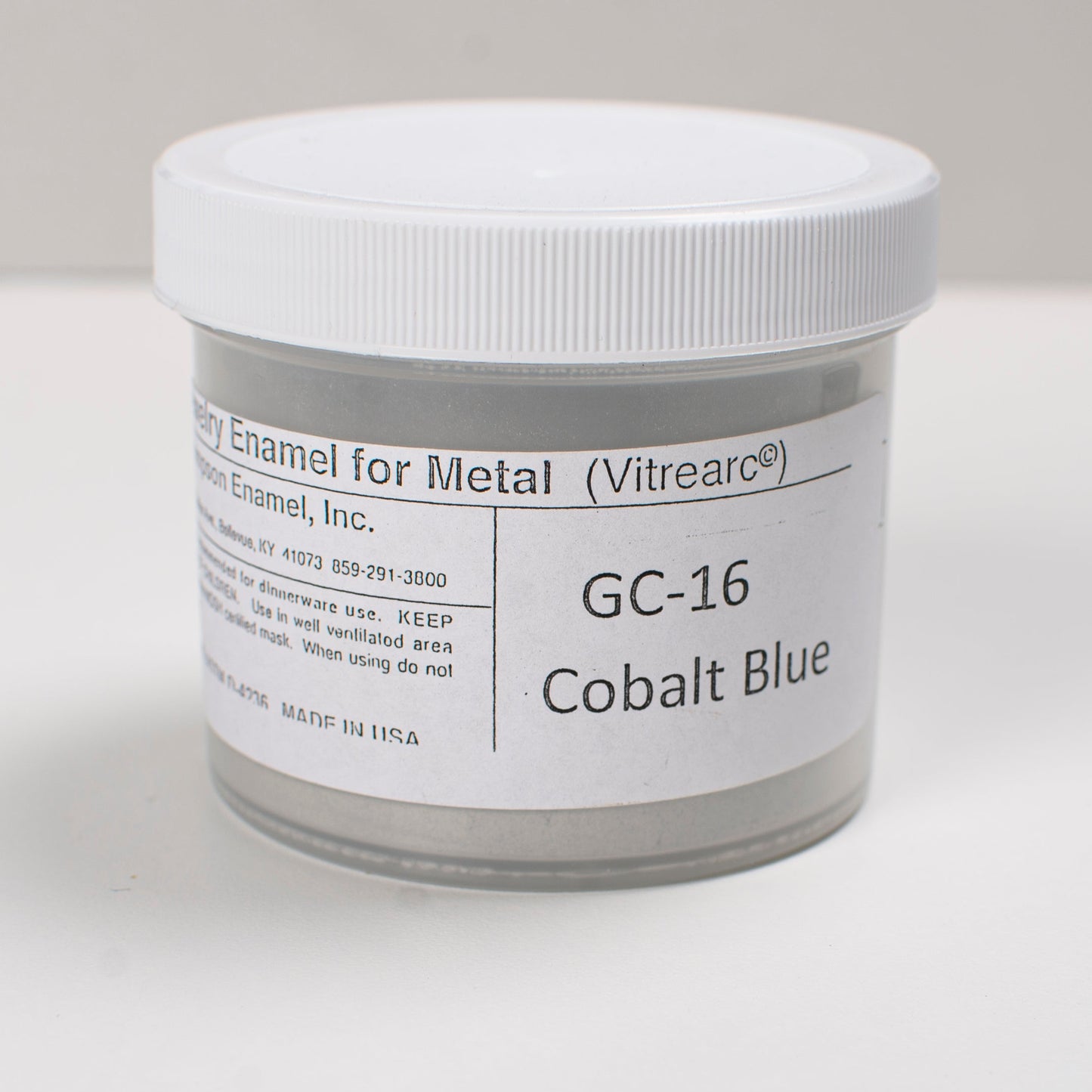

THOMPSON enamel

Ground Coat for Enamelling Iron 15g, 25g, Liquid Form Enamel Cobalt Blue (Actually Grey), Dry Enamel Powder, Ground For Steel

Ground Coat for Enamelling Iron 15g, 25g, Liquid Form Enamel Cobalt Blue (Actually Grey), Dry Enamel Powder, Ground For Steel

Couldn't load pickup availability

Ground coat for enamelling iron or steel metals, cobalt blue colour (actually grey). 25g. Liquid Form Enamels – Water Base.

1pcs

Choose the quantity - 15 g. or 25g.

For spraying or dipping. Add water to thin if necessary. Can be mixed to create many colors. Ceramic pigments may be added to additionally create other colours. It contains a workable blend of glass, clay, and electrolytes. You need to add only water. Colours can be intermixed when in liquid form to create new shades of color.

Mixing Instructions for Dry Powder:

For small items a simple way to mix is to place a half teaspoon of powder into a plastic spoon. Using an eye dropper, add drops of water until the mixture is the consistency of ‘milk’. Apply to copper with a brush. Always make sure the powder and water have been stirred right before application as the glass falls out of suspension in the water very quickly.

Firing Instructions:

Make sure enamel product is completely dry before firing. For small pieces (less than 2” in diameter) fire at 1450 degrees F. for 1-1/2 to 2 minutes. For larger pieces (up to 6” diameter) fire at 1450 degrees F. for 2 to 3 minutes. For much larger work, firing times & temperatures should be determined for your specific project. Firing times and temperatures are meant as a guide only. You may need to adjust up or down for your own situation/equipment.

For larger quantities, mix ¼ cup water to 5 oz. powder. To make a gallon of liquid, mix 14 lbs of powder to 2 quarts of water. The water to powder ratio may be adjusted up or down if needed for your particular project. If the liquid dries out, you can grind it back smooth in a mortar & pestle to re-constitute.

WARNING

1. Wear protective gear, including gloves, a face mask, and safety goggles, to prevent skin contact, inhalation, and eye irritation when handling enamel powder.

2. Work in a well-ventilated area or use a fume hood to minimize exposure to potentially harmful fumes and dust from the enamel powder.

3. Keep enamel powder containers tightly sealed when not in use to prevent accidental spills and minimize dust dispersion.

4. Avoid eating, drinking, or smoking while working with enamel powder to prevent ingestion and contamination.

5. Wash hands thoroughly with soap and water after handling enamel powder to remove any residue and prevent accidental transfer to eyes, mouth, or skin.

6. Follow manufacturer's instructions for mixing enamel powder with the appropriate medium and applying it to jewelry pieces.

7. Use designated tools, such as a sifter or scoop, to measure and transfer enamel powder to minimize contact and prevent cross-contamination.

8. Store enamel powder in a cool, dry place away from direct sunlight and heat sources to maintain its quality and prevent degradation.

9. Dispose of unused or expired enamel powder according to local regulations and guidelines for hazardous material disposal.

10. Keep enamel powder out of reach of children and pets to prevent accidental ingestion or exposure.

11. Powdered enamel which contains Borax suspected of damaging fertility, may damage the unborn child.

It remains the user's own responsibility to make sure that the information is appropriate and complete for his special use of this product.

The item will be sent from Lithuania by registered priority mail. Usually delivering takes from 1-2 (EU) to 2-5 (US, UK, Canada, Australia, etc) weeks. More info in shipping policy.

ALSO WE DO OFFLINE MASTER CLASSES OF MAKING JEWELRY AND ART OF ENAMELLING! YOU CAN WATCH OUR STUDENTS WORK AT INSTAGRAM HIGHLIGHTS: https://www.instagram.com/nikoloz_jewelry

Tested by Nikoloz jewelry

www.nikolozjewelry.com

Share